The Path of a Dream: Create Sneakers From Zero

How We Create Our Sneakers From Scratch: The BANBROKEN Process

How We Create Our Sneakers From Scratch: The BANBROKEN Process

Introduction

In this episode of the BANBROKEN podcast , we take you behind the scenes of the process of creating our sneakers from scratch. We explore the challenges, strategic decisions and secrets that have allowed us to turn an idea into a tangible, high-quality product. Join us as we reveal how we have managed to revolutionize the footwear market.

The Beginning of a Dream: Creating Sneakers from Scratch

The idea of creating sneakers was born from a restless and non-conformist desire to seek new challenges. Since we started BANBROKEN, we always had the dream of being able to dress a person from head to toe. This project represented the biggest challenge we have faced in our 9 years of existence. It started as an innocent idea, but quickly transformed into a clear mission: to create the best sneakers possible, and thus fulfill our dream.

The Challenge of Excellence: Overcoming Obstacles in Manufacturing

From the beginning, I knew it would be a path full of falls and rises. Although I had the help of an extraordinary team, I faced much of the process alone. I found myself immersed in every detail, from the design to the selection of materials, always with the vision of creating a product of excellence. The search for suppliers was one of the first challenges, since I tried to produce the shoes in Spain, but due to machinery and cost limitations, I decided to move production to China, where the most advanced factories in sports footwear are located.

Strategic Collaborations and the Challenge of Working with International Factories

Upon arriving in China, I found a top-notch factory, but the language barrier and cultural differences made communication a challenge. Despite the difficulties, I worked closely with a team of experts to develop every part of the shoe, especially the sole, which was designed to offer versatility in both running and strength training. This was a long and meticulous process, which included working with engineers to capture exactly what I had in mind.

Financing and Crowdfunding: Transforming an Idea into Reality

After overcoming the initial design and manufacturing challenges, we faced another major challenge: financing. When developing a product as innovative as our sneakers, we knew the investment would be considerable. At a time when we had already invested in other projects such as new knee pads and clothing collections, we decided to opt for crowdfunding as a viable solution to finance production.

Crowdfunding, through the Kickstarter platform, allowed us not only to raise the necessary funds, but also to validate our product in the market. Despite the complications and lack of clarity in communicating the concept to some of our followers, the support we received was overwhelming. In an event we organized at Crossfit Al Ándalus, we managed to meet our minimum funding goal in just two hours, which gave us the necessary impetus to continue with the project.

Overcoming Obstacles in the Production Process

As we moved forward with production, we encountered additional challenges, such as delays in delivery times and issues with the sole molds, which had a significant cost. Each mold cost around $3,000, and with the need to make shoes in various sizes, the total investment in molds alone was considerable. Despite these obstacles, we continued forward, adjusting and improving every detail of the design.

Additionally, during the production process, we faced unexpected changes from the manufacturer, forcing us to make adjustments and re-evaluate quality to ensure the final product met our high standards. This process included multiple factory visits and the implementation of mechanical testing to ensure the durability and functionality of the shoes.

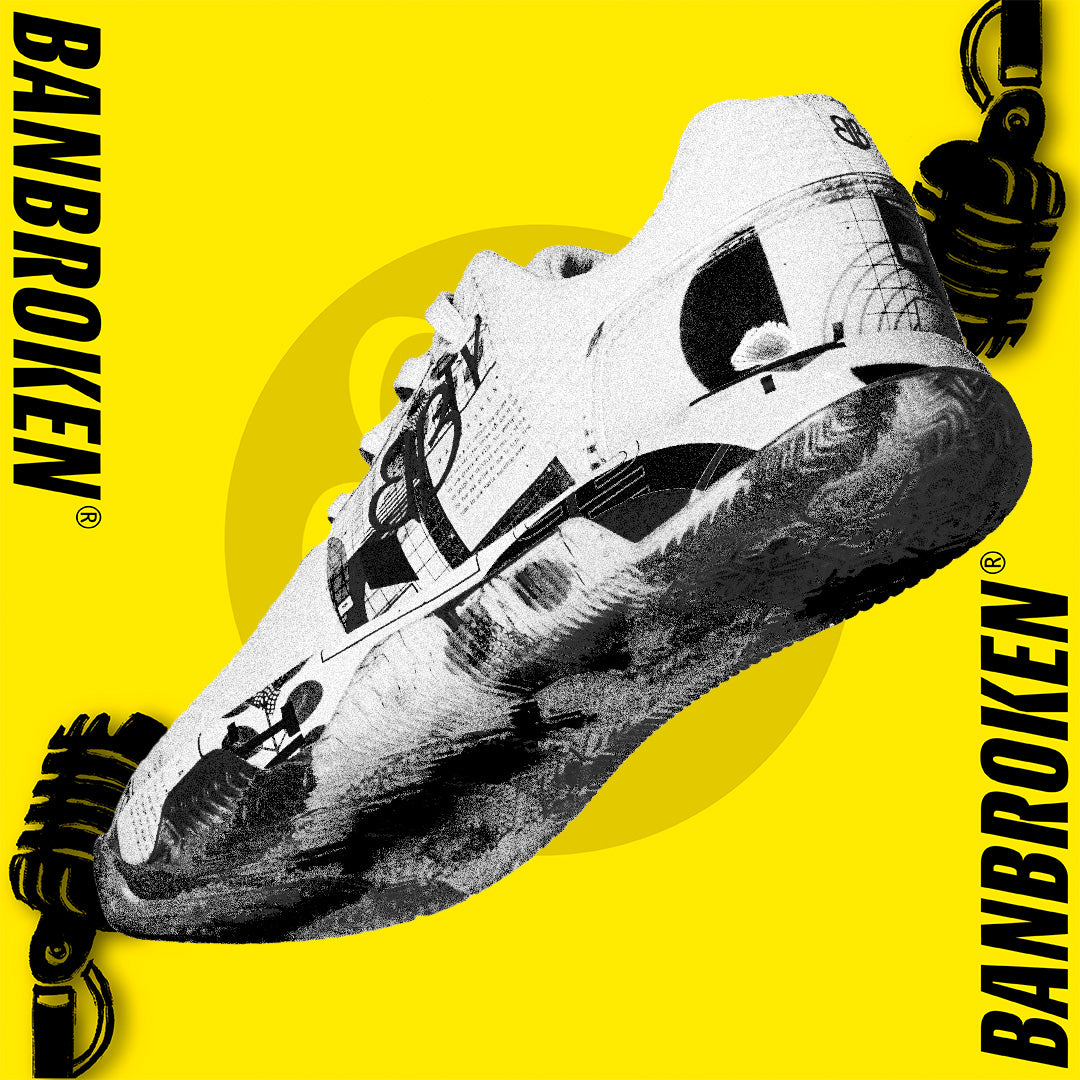

The Perfect Design: Innovation in Every Detail

The design of our shoes is specifically optimized for functional training, offering versatility that few shoes on the market can match. The sole has been designed to provide optimal cushioning, with a density adjusted after multiple tests. Additionally, the shoes feature innovative features such as anti-chafing nubs and micropigmentation in key areas to resist wear and tear during intense workouts, such as rope climbing.

One of the biggest innovations we have introduced is the inclusion of NFC technology in the shoes, which adds an additional layer of functionality and reflects our commitment to constant innovation.

Conclusion

The process of creating our sneakers has been a challenging but rewarding journey. If you are passionate about product design and want to know more about how we create high-quality footwear at BANBROKEN, subscribe to our podcast and follow us on our social networks. Don't miss any details of this exciting adventure!

Leave a comment